How to Choose 3D Printing for Product Design: Benefits and Uses

Image from Pixabay

New technical opportunities allow creative specialists to implement their unusual, ambitious, and daring ideas in reality. Indeed, why not facilitate your work greatly and make an indelible impression on the customer due to such effective technology as 3D printing? This method is actively used by large construction companies and small architectural and design studios.

And here, you may ask a completely logical question: how to choose 3D printing for product design? So you're lucky since, in this article, designers, media creators, project managers, and design readers will find a helpful checklist of the nuances to consider when choosing a device appropriate for their needs.

3D Printing in Business: New Possibilities and Benefits

Every business's clients are significant, and their satisfaction is essential to any marketing strategy. By staying ahead of the competitors and giving clients what they want, 3D printing has transformed how modern companies meet challenges. Moreover, customer expectations have also changed; they want to get product design quickly and efficiently. So, 3D printing has plenty of pros.

Many companies have begun implementing 3D printing into their processes, trying to benefit from it. And it's not surprising since, in recent years, it has grown enormously and continues to develop its current achievements. Considering all the pros of 3D printing, it's evident that it has quickly become a technology that will replace typical methods. It's only a matter of time. And below, you'll find a convenient table summarizing the main benefits of 3D printing for today's businesses.

| Benefit | Description |

| Cost Optimization | The range of 3D printer materials used for printing is increasing every day, and in recent years you can optimize the final cost of the product even better. In addition, 3D printing reduces the distance by which the product will be moved. Since such devices help the specialists design a product from start to finish, they can develop it in one country and email it to another to prepare it for manufacturing. Thus, it makes 3D printing an industry that can be used worldwide without sea, air, and road transport. |

| Less Waste | Typical production is a subtractive process in which raw materials are lost and reused repeatedly, resulting in high costs and waste. The benefit of 3D printing is a unique way to create a product with minimal waste, known as additive manufacturing. However, it still takes time and effort to determine how and when that waste will be used. So high-volume 3D printers efficiently resolve this issue. |

| Saving of Time | Modern people live in a fast-paced world where today's tasks should have already been done yesterday. And that's where 3D printing comes in handy. One significant advantage is that parts and products can be made much faster than traditional methods. For example, complex designs can be created as a CAD model and translated into reality in a few hours. In addition, it brings design ideas to life so that they can be quickly tested and developed in a short time. In comparison, typical methods can take weeks or months from the design stage to the prototype stage through the manufacturing process. |

| Competitive Advantage | Companies can create quality products in a shorter time, providing a competitive advantage. Creating life-size prototypes allows designers to think differently about the products they develop. Plus, with such prototyping, you can talk to your partners, investors, and customers in the same language about a product that enters the market on the other side of the world. So 3D printing lets you quickly create a concept that people can physically hold in their hands, eliminating any fears or misunderstandings. Then, you can make changes to the product design until the very last minute. It means that 3D printing provides a unique and valuable way to determine if a product has the potential to reach the market or not. |

| Reducing the Number of Errors | 3D printing creates a product in one step, with no interaction with operators during this process. All you need to do is develop the design and upload it to the printer. Thus, it eliminates dependence on many production processes and increases control over the final product. |

| Confidentiality | Continuous prototyping and production on your 3D printer ensure that designs never leave the company premises, protecting your intellectual property. No third parties can ever claim your innovations. Every new design is kept in-house, so you no longer have to worry about confidentiality. |

8 Nuances to Consider Choosing a 3D Printer

Image from Pixabay

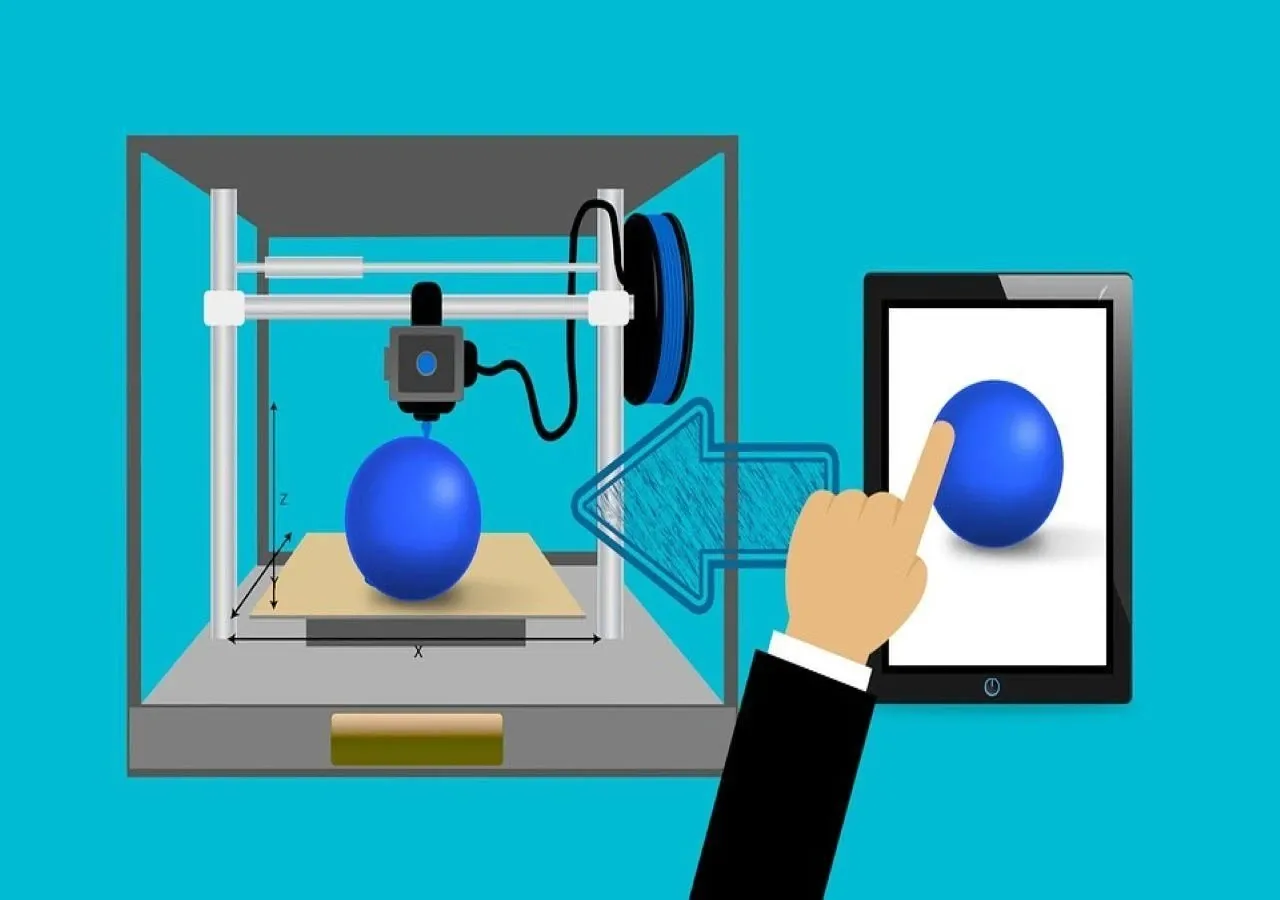

So, it's time to answer the main question concerning choosing the suitable device among various 3D printers. But first, you need to consider what tasks you want to solve due to it and what features the 3D printer should have to solve these tasks. After that, you can continue reading this article, which surely helps you with your choice and saves time.

# 1 Decide on 3D Printing Technology

The first thing to do is to decide on 3D printing technology. So you’ve got two main ways to do it. If you deal with high-precision and miniature products, such as jewelry, you’ll fit 3D printers using SLA or DLP technology. Such printers are designed specifically for the production of high-precision models. 3D printing in these devices is done via a laser beam that shines the photopolymer resin. Hence the accuracy of manufacturing models. Striking representatives of this segment: 3D printer Form 2 or 3D printer B9Creator. If you have a more comprehensive range of tasks, more critical functionality, the size of the details, and low manufacturing costs, then you approach the FDM printer.

# 2 Assess Your Needs Soberly

Of course, people always want the best and with maximum capabilities. However, do you need it all for your current tasks? So what can you give as an example? For example, the size of the working area of an FDM 3D printer. On the market, there are printers with a large print area (1m x 1m x 1m) and tiny (100mm x 100mm x 100mm). But for most tasks, there's a certain standard already.

The printing area lies within 200 x 200 x 200 mm, with slight fluctuations in size in one direction or another. Most 3D printers have this size of working area, which is enough for 95% of all tasks. But there are variations. If you plan to make small parts, the smaller size will probably be enough for you. But if your work involves making large prototypes, it only makes sense to pay attention to a printer with a large print area.

# 3 Decide on the Complexity of Products

It would help to decide how complex models you will print on a 3D printer. If you plan to make complex prototypes or sophisticated art models, you need a 3D printer that can print in two materials. It is so that your printer can print support from soluble material. If the models are not going to be the most complicated, you can get by with a single extruder and save your budget. A complex model is a model with many elements hanging in the air or whose details have angles greater than 30 degrees.

# 4 Think of a List of Materials to Use

It's essential to determine a list of possible materials you will print. First, it applies to materials with a high degree of shrinkage, such as ABS and Nylon. You need a 3D printer with a heated table to print with such materials. And it is very desirable to have a closed enclosure to provide a thermal circuit around the model.

For example, suppose you plan to print only PLA. So, in this case, you don't need a heated table. But it's still better if the printer has it. These days, the price difference between printers with a heated table is almost the same as printers without one. But you get a versatile solution with which you can perform the full range of tasks lying before the 3D printer.

# 5 Look at Design and Kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you're not a prominent technological expert, you can immediately see that some printers have an open design. Others are closed. So what does this appearance tell you? Open-design printers usually have horizontally moving table kinematics (based on Prusa 3D printers).

However, this kinematics has some cons, such as not having the fastest printing speed and possible problems with the printing quality related to the adjustment complexity. It is what is known as wobbling. Also, the lack of a closed case can cause problems with the print quality of plastics with high shrinkage (ABS, Nylon).

Enclosed printers are built with a lift table scheme. And they lack most of the cons of the previous group of printers. They usually have a closed body, which allows maximum quality printing with high shrinkage plastics. Printers with a closed casing have a more rigid design, allowing higher-quality printing. Different designs represent the kinematics of the print head. Of course, they have their pros and cons. But most of them have benefits over the schemes of printers with a moving table.

# 6 Consider the Nozzle Diameter

Most 3D printers on the market come with nozzles with a diameter of 0.3-0.4 mm. It's enough to solve most tasks for a typical 3D printer. You can install a different diameter nozzle on some devices but not on others. As mentioned above, the need to print with nozzles less than 0.3-0.4 mm in diameter occurs rarely. Mainly it concerns personal experiments or some particular tasks.

If you don't plan to do that, this feature isn't so necessary. And what is meant by specific tasks? It refers primarily to printing large products, where it's crucial to reduce printing time. Consider that the ability to change nozzles is a vital necessity for printers with a large print area. So, as with the heated table, the ability to change nozzles is a nice bonus. Again, it isn't necessary, but beneficial if you don't have to pay extra.

# 7 Pay Attention to Layer Thickness

It's essential to understand that most models on a 3D printer are printed with a layer thickness of 0.1-0.2 mm. These optimal values allow you to achieve quality and acceptable printing speed. A certain number of printers will enable you to print with a layer less than 0.05 mm, and get very high-quality prints. But then there's the problem of drastically increasing printing time. And if you care about this printing quality, it probably makes sense to pay attention to 3D printers, as mentioned earlier. But, again, it's about devices that use SLA or DLP technology.

# 8 Finally, Don’t Forget About the Types of 3D Extruders

You can find two main types of extruders available today. These are the Direct-drive extruder in which the bar motor is located on the printhead. And the so-called Bowden extruder, where the plastic feed motor is placed on the housing. And the plastic itself is fed to the extruder through a PTFE tube. So what are the pros and cons of each extruder type?

Due to the absence of a motor on the printhead, the Bowden extruder has less weight. And therefore, it has greater positioning accuracy, which has an impact on print quality. And a higher travel speed, which consequently positively affects the printing rate. But it does have one significant drawback. It's usually quite challenging to print flexible plastics on a Bowden extruder.

This extruder shows all its positive features when using laminates with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the standard 1.75 mm plastic. Therefore, printers with this type of plastic are often deprived of the opportunity to use new materials. First comes in the most common 1.75mm form factor. A direct extruder usually doesn't have a big problem using flexible laminates. Easier to set up, but due to the greater mass of the printhead, it's inferior to the Bowden extruder in terms of speed and positioning precision. What do you prefer? That is your choice. Of course, there are many more nuances when choosing a 3D printer. But even this list will make you examine some points you may not have thought about more carefully.

Conclusion

3D printing is a fast-growing industry with significant future potential since it can make human life more accessible and comfortable. And as 3D printing grows as fast as creative professionals come up with new product designs, it may not be long before people live in a world where they can 3D print their dinner, a custom-made dress, or spare parts to repair everyday items from the comfort of their own homes.